When leaders think about what they need most to improve their supply chain processes, soft skills like change management and collaboration may not come to mind immediately. But APQC’s 2024 Supply Chain Priorities and Challenges research with supply chain professionals found that many of the biggest barriers to process improvement in supply chain come from a lack of these skills.

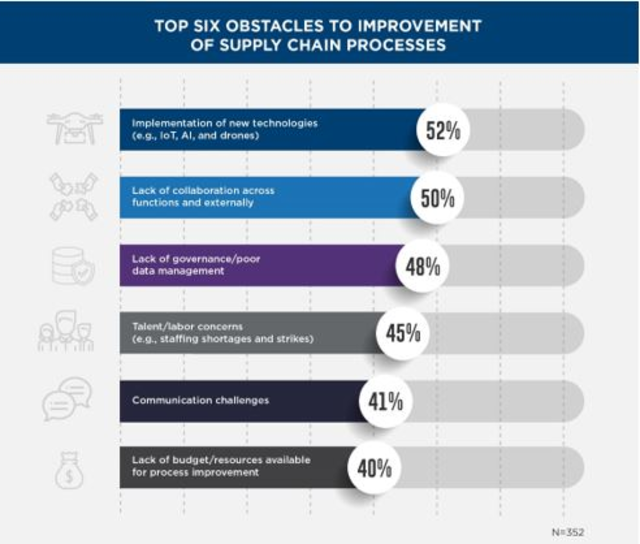

When APQC asked respondents about the about the top obstacles they face when trying to improve supply chain processes, half of them cited challenges related to implementing new technology (52%) and lack of collaboration (50%). Poor collaboration within and among supply chain and other functions (internal or external) can be just as damaging as poor change management around new technology and it continues to persist as a top obstacle for the third year in a row. Without strong foundational elements like data management (48%), new technologies only accelerate problems that already exist in processes (Figure 1).

APQC Fig. 1

APQC Fig. 1

New Technology Requires Change Management

Respondents said that the top obstacle to improving supply chain processes in 2024 is the implementation of new technologies (e.g., AI, drones, Internet of Things [IoT] sensors, etc.). This ranking reflects the increased need for change management, as organizations reckon with the ways in which new technologies require process changes, new roles, new forms of governance, and more. Far from being ‘plug and play,’ many important forms of supply chain technology like risk notification systems are only as good as the data, processes, and governance that sit at their foundation.

Supply Chains Continue to Suffer from a Lack of Collaboration

Lack of collaboration was the top obstacle to supply chain improvement in 2022 and remains the second most common obstacle since 2023. While a lack of collaboration is challenging for any area of the business, it can be toxic in a supply chain context. Disconnects in the supply chain can lead to ripple effects that impact customers and their ability to receive orders on time in full, damage-free and with accurate documentation. Supply chain leaders need effective internal and external collaboration to be resilient and responsive to change, especially with increased uncertainty in 2024.

Governance and Data Management are Foundational

Nearly half of respondents (48%) said that a lack of governance and/or poor data management practices were an obstacle to process improvement. Governance and data quality are intimately linked: Someone in the organization needs to be formally accountable for ensuring the availability, quality, and security of data that is vital for supply chain.

Lapses in governance and other poor data management practices can quickly cause problems for supply chains. No matter how advanced an organization’s analytical tools are, forecasts built from bad data can still lead decision makers in the wrong direction or keep them from identifying key opportunities. At the very least, supply chain processes become less efficient when decision makers have to check and re-check the numbers because the data is unreliable.

Overcoming Obstacles

Flexibility is a virtue for supply chains—especially in times of change and uncertainty. Fortunately, more organizations than in any other year of APQC’s research (84%) report that they have evaluated and modified their supply chain strategy to help head off the obstacles they are facing. For some industries like aerospace and pharmaceuticals, the challenges of 2023 led as many as 89% of organizations to modify their strategies.

As you review your organization’s strategy for 2024, look for opportunities to embrace change management and enhance collaboration. Internally, these opportunities could be a simple as meetings where experts gather with mid-career and novice employees to learn about current topics of interest. Externally, look for opportunities to connect with your most strategic suppliers to jointly develop solutions to common problems. While internal collaboration accelerates expertise and helps build collaboration and communication skills within your team, external collaboration is critical for forging new paths in the face of supply chain uncertainty.