The modern warehouse is no longer simply a space for storing and shipping products. While traditionally packaging manufacturing and warehousing have been distinctly separate industries, the lines between the two are starting to blur. Until somewhat recently, packaging was manufactured separately and transported to warehouses, often resulting in mismatched sizing and excessive material use. New advancements in automation are now allowing companies to bring packaging materials into the warehouse. Using automated right-sized packaging solutions, boxes can be tailored within a warehouse to perfectly fit specific SKUs, minimizing waste, reducing costs and enhancing the customer experience.

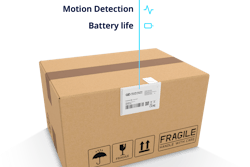

While the concept of right-sized packaging has been around for decades, new technologies in the market are changing the game. At the forefront of the transformation to right-sized packaging are the advanced systems that collect, analyze and leverage data within the warehouse. So how does it work? These systems integrate cutting-edge automation and machine learning to optimize processes, ensuring that packaging is both appropriately fitted and structurally sound. A comprehensive analysis of packaging materials using 2D and/or 3D imaging is conducted to determine carton integrity, identify labels and assess the contents of a shipment to ensure boxes are the best size for the products they will hold. Backed by AI, this technology also provides valuable business insights driving constant operational improvements and more comprehensive quality control.

As e-commerce demand continues to surge with no end in sight, brands are increasingly taking notice of right-sized packaging and its potential to transform its warehouse operations to deliver a more customer-centric product while enhancing its sustainability and efficiency efforts.

Unlocking Sustainability Gains

One of the most profound benefits of right-sized packaging is its alignment with an industry-wide focus on sustainability. Implementing more sustainable operations is becoming a key priority for companies that traditional packaging methods do not support. These more conventional packaging practices often result in excess material through oversized boxes, unnecessary padding and inefficient shipping. Right-sized packaging reduces packaging material waste by minimizing empty space and fitting boxes to the exact dimensions of a product.

This more sustainable packaging method also utilizes corrugated materials that aren’t compacted with other waste. This virgin material has a higher recycling value, making it easier to deconstruct and repurpose. Incorporating these purer elements can also reinforce the tensile strength and stiffness of the box, protecting the product in a way that is simple for the consumer to dispose of responsibly. As the packaging industry continues to trend toward using fewer materials, less adhesive and more sustainable options, brands can significantly reduce their adverse impact on the planet in this area of their business. Additionally, it’s a topic that consumers increasingly care about. In fact, approximately two thirds of consumers note sustainable packaging is at least somewhat important in their overall purchasing decision.

Reducing Labor Costs

Right-sized packaging is advantageous in lessening labor costs and utilizing talent more effectively. Automated systems not only manage the creation of custom packaging, but reduce the number of touches required as a product moves through a packaging line as well. With less of a need for manual intervention in repetitive, tedious tasks, employees can focus on more complex, high-value work inside the warehouse rather than spending time sizing and cutting boxes. This labor savings is also transformative for kitting, where individual components of an item are bundled together in a singular box. With right-sized packaging technology, warehouses can now automate this process, markedly reducing the time and worker involvement required to prepare orders for shipment and instead use labor more effectively.

Providing Cost-to-Ship Savings

The savings associated with right-sized packaging extend to shipping costs and rates as they are heavily influenced by the size and weight of packages. Carriers often charge more for oversized or underfilled boxes, resulting in higher shipping costs for businesses. This becomes less of an issue when boxes are created to fit a product exactly as dimensional weight and excess space are reduced. Appropriately sized packages also allow for more efficient and uniform palletization, which cuts down a company’s cost-to-ship in terms of transportation capacity, the number of trips required and fuel consumption. Avoiding the upcharges that come with needlessly large deliveries leads to considerable savings over time.

Improving the Customer Unboxing Experience

Customer satisfaction is increasingly tied to the unboxing experience. With the rise of e-commerce, consumers have come to expect packages that are thoughtfully designed, easy to access and protective of the product inside. After all, the unboxing experience is the consumer’s first tangible interaction with the product, so it’s imperative brands get it right. Right-sized packaging plays a crucial role in delivering on these expectations. By tailoring packaging to the product’s size and shape, companies mitigate the risk of damage during transit. Products that arrive intact help drive customer loyalty and reduce the likelihood of returns, which is both a financial and environmental win. Customized solutions also allow companies to design packaging that reflects their brand identity, offering a sense of cohesion with their online presence and the physical items delivered. Right-sized packaging is not only beneficial in terms of how the box is opened, but also how the customer will dispose of it. Boxes that are more precisely fitted to the products are easier to recycle by the recipient, minimizing unnecessary waste.

The Future of Packaging

As the packing industry continues to evolve, the focus is shifting from developing new products to developing new systems. Right-sized packaging is a prime example of this transition and marks a fundamental change in the industry as we continue to see adoption spike. By creating modular, repeatable solutions that prioritize sustainability and efficiency, companies can revolutionize their warehouse operations and deliver a better end product to strengthen the customer experience. Ultimately, right-sized packaging represents a better way to deliver by helping to enhance efficiency, provide savings and ensure that items arrive at their destination in pristine condition, all while minimizing the impact on the environment.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)